Create depended assembly parts using

blocks

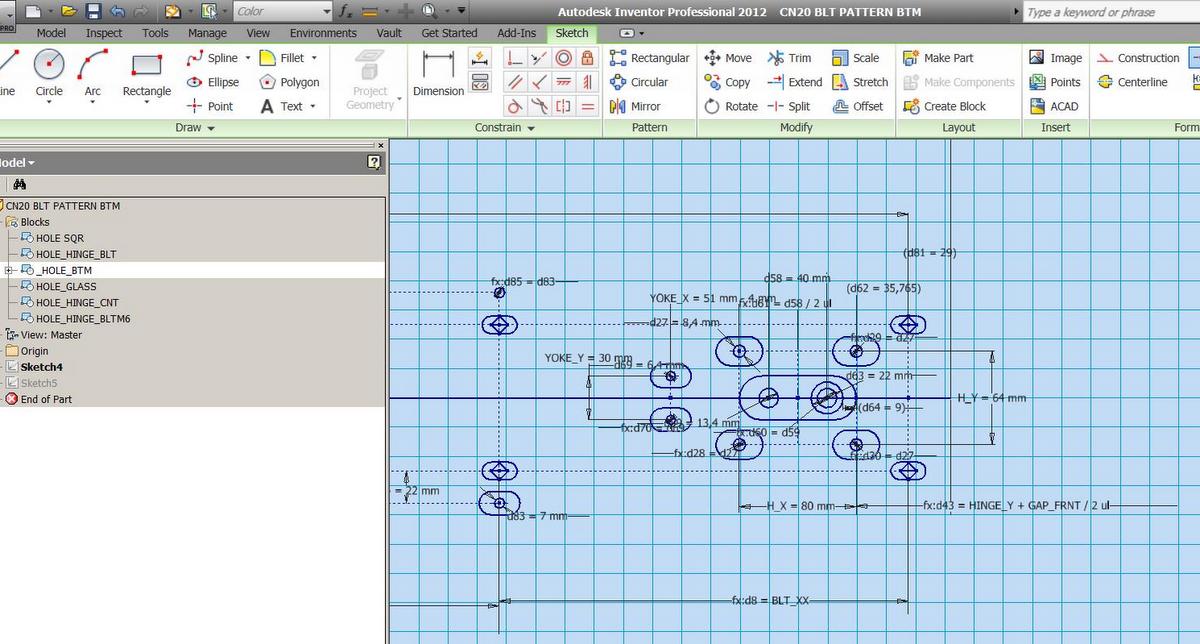

Did you ever match a bunch of

holes and shapes at one part with others while making an assembly?

Pic.1

And let add some real design-in-progress

stuff – those holes may eventually changed at the base part and it will require

the changes at all depended parts. How boring and time consuming to change

everything and oops.... some other depended parts will show not appropriate change.

When you see it you probably already spent a while to change almost all

previous depended parts… The fresh idea of changing some design of the base

part may perish just from one thought of changing a dozen parts to fit the

change done on basic part. Along with this manual changes the errors could be

easily done.

So here is idea of tie-up

depended parts by their parameters come up.

There are several ways to make

parts depended from each other, by Excel file, by linking the parameters from

other part or by creating the single IPT file with all necessary parameters

called as Drive Sketch.

Each mentioned way has one time

consuming thing in common. Literally we must create depended stuff from scratch

at every new part using linked parameters taken either from the same Excel or

the same drive sketch or other part. This is quite time consuming way and if

depended holes or special designs are complicated it takes a long and boring

while. This process is also vulnerable for errors.

The other way is create depended

parts using a Derive but this function will force us to create a part in the

same coordinates, other words in absolutely not flexible way.

The one more problem is the

assembly does not have all depended holes same in design. For example you

should match a round bolt hole in one part with round-extended hole in other

part and some other design for a third part as you can see on picture 1.

Depended parts could be absolutely different in overall shape as they are in

real assembly but have dependency in the holes pattern and shape. As you can

see at example at picture 1 the parts #1,#2 and #3 are fit each other but have

different holes shape and different in overall shape.

Making depended parts

Chapter 1. The proposed way is a mix of Drive Sketch and Deriving

technique with using Blocks and it is quite simple. From the beginning let’s talk about an assembly designing from

scratch.

Initially let create a new ipt

file with a single sketch with all necessary holes and shapes which fit each

other as they must correspond and fit each other between depended parts. It

will be the one Drive Sketch for all depended files. As seen from pic. 2 the

round extended holes are correspond to square shaped holes and other bigger

round extended holes are fit for round holes for bolts.

Create a block based on the holes

and shape pattern. This pattern may include the fold-in simple blocks as you

can see on picture. For instance the round extended holes are blocks. In this

way it will be much easier to spread them all over the pattern and make no

errors. Assign a name for this Block to make it easy to find it later.

Pic 2

Create or take existing part you

need to be depended and make a Derive of the Drive Sketch file you just

created. Choose the only block(s) you just created, see pic 3. Rule out Sketch

and other stuff you do not need.

Pic 3

Now you are flexible and free in

positioning of this block in this part. You can place it wherever you want not

depending from planes and coordinates. Create a new sketch and place the block

there. Once you make this block fully constrained it will change a color as

fully constrained part. All process of inserting and constraining takes just

few clicks compare to creating the similar pattern using linked parameters, see

picture 4. This linked block is not accessible for editing. It could be changed

only in original Drive Sketch. This block could be mirrored.

Pic 4

As seen from picture 4 the

Sketch23 consisting the only one block derived from Drive Sketch file. Choose

the required holes for this part and cut them. Use

Ctr+Select if you accidentally choose a wrong hole.

Choose and make required holes on

all depended parts, see pictures 5 and 6.

Pic 6

As you can see from pictures 5

and 6 you can choose the required for certain part holes and be sure they will

always fit each other as they fit at the Drive Sketch block. Once changes will

be done to the Drive Sketch block they will affect all depended parts at once.

You can be always sure all depended parts are fit each other after every change

done to single Drive Sketch block. You also can be sure all shapes will be

changed properly at all depended parts.

Chapter 2. This way of making depended parts can tie up some group

of parts depending from one base part(s) dictating the holes pattern or special

shapes or many etc. You will be lucky if holes pattern will be evenly spread

and could be easy duplicated by Pattern tool with exporting just several

parameters.

Mostly

in real assembly holes patterns are not evenly spread and making the same and

depended pattern at other depended part yon can be finally lost in dozens of

tie-up parameters and errors and spend a lot of time

ADVATAGES

·

Easy and vivid way to make depended parts

without big efforts.

·

Any alterations in parameters and depended

shapes are done at same and single Drive Sketch; it is not required to jump

between rows of depended parts to make changes in each file.

·

Much less errors due to “forgetting” to make a

change or wrong change in some depended part.

·

All holes and shapes are visible at same

pattern; this will make less effort changing them correctly and all from one

step. For example we started with M6 bolts and then decided to change them to

M8. All holes and special shapes in depended parts must be changed to other

size. So we see all depended holes at the same sketch and have much less

chances to miss some changes because we clearly see all of them.

·

It resembles the nature way of creating a

puncture stamp and does different parts with exactly the same pattern. Compare

to tie-up parts by linked parameters we can create less errors when we will

change the initial sketch.

·

We can add or deduct additional shapes and holes

in our Drive Sketch and we will instantly have them available at all parts.

Just imagine we decided to set one more fixture and we create some new holes

and corresponded holes at Drive Sketch block and here is a miracle begins. All

we need is to choose fresh holes at our parts and cut them. They are already at

the right place! If we would do it by parameters we should update the linked

file, then choose the new parameters, then create the new hole – at least

several times longer and vulnerable to errors.

·

Easy way to keep some standards on common and

special holes and shapes between all depended parts in assembly since we use

the sole source and do not creating them from scratch at each file.

·

This way also exports the engaged parameters as

long as Derive is used. By editing the derived parts you can also add some more

required parameters from base part without need to make an additional link

between base and depended parts.

Importand.

1.

Make Rebuild All after each Drive Sketch block

change at main assembly or depended parts. Inventor not always automatically

follows all changes made to Drive Sketch block.

Regards,

Orest Yavtushenko, Chief

Designer, Holography Ltd

This article is about easy and sure way of making the depended parts in

the assembly while making a new assembly design. The goal of making depended

parts is changes we will make to one basic part will affect all depended parts

automatically without need to change depended parts manually one by one